ABOUT US

关于我们

厦门凯纳石墨烯技术股份有限公司

厦门凯纳石墨烯技术股份有限公司(简称:厦门凯纳)位于福建省厦门市海沧区,注册资金4610万元人民币,集石墨烯研发、生产、销售和应用开发于一体,是国家级专精特新“小巨人”企业、国家级高新技术企业、福建省科技小巨人领军企业、厦门市科技小巨人领军企业、厦门市“双百计划”人才企业,石墨烯制备与应用技术获得福建省科学技术发明奖一等奖。企业通过IATF16949、ISO9001、ISO14001、ISO45001等管理体系认证,参与了多项石墨烯国家和行业标准的制定工作,现已申请100多项发明专利和20多项中国注册商标,在技术水平、品牌知名度等方面位居行业前列,是中国最早的石墨烯企业之一。

-

2010 年

公司成立

-

4610 万元

注册资金

-

500 +

全球客户

厦门凯纳 | 石墨烯行业领先者

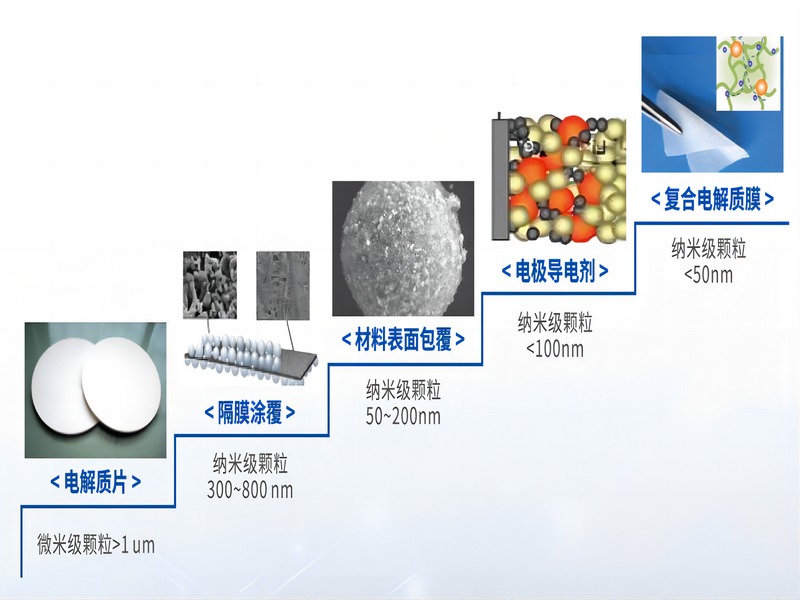

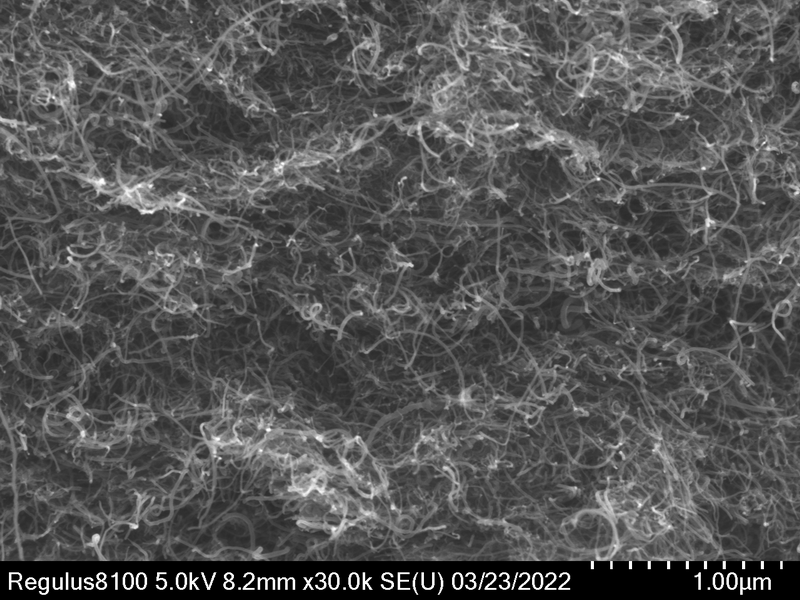

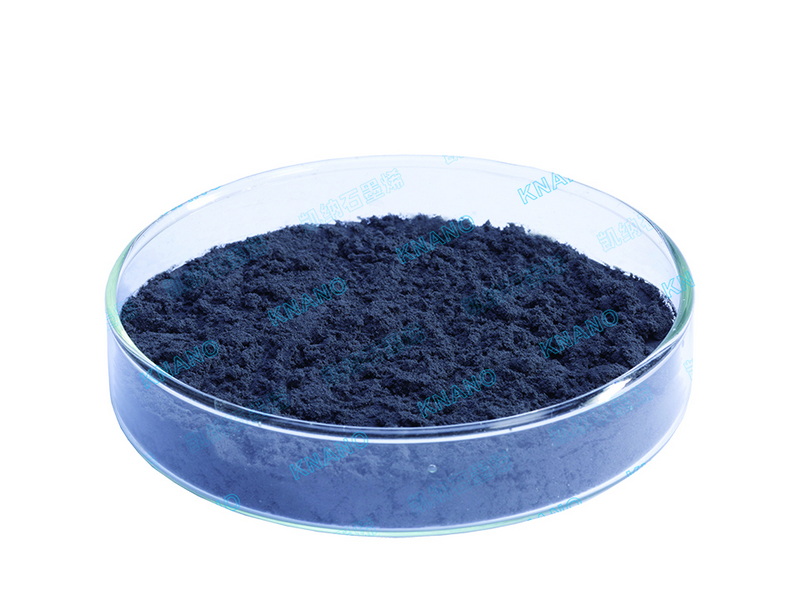

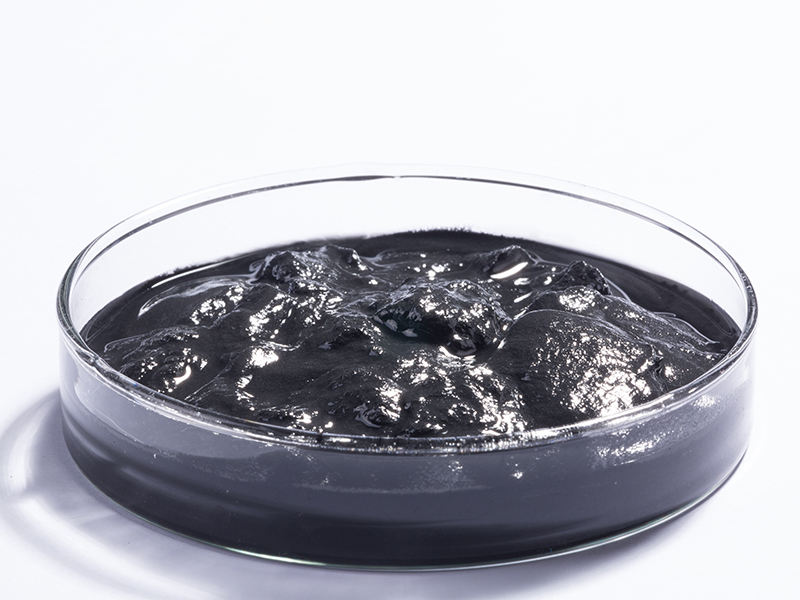

厦门凯纳的石墨烯产品可显著改善材料的导/散热、导电、阻隔、光/热稳定性等性能,作为高性能的添加剂材料,

广泛应用于新能源锂电池、钠电池、塑胶、涂料、油墨、纺织、膜材、界面材料等领域。

如需了解更多信息,请与我们联系。

CORPORATE NEWS